Engineered Systems

Hydraulic Flushing Systems

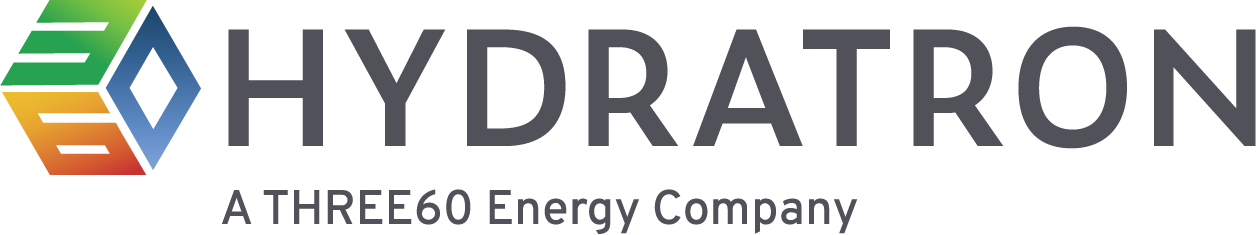

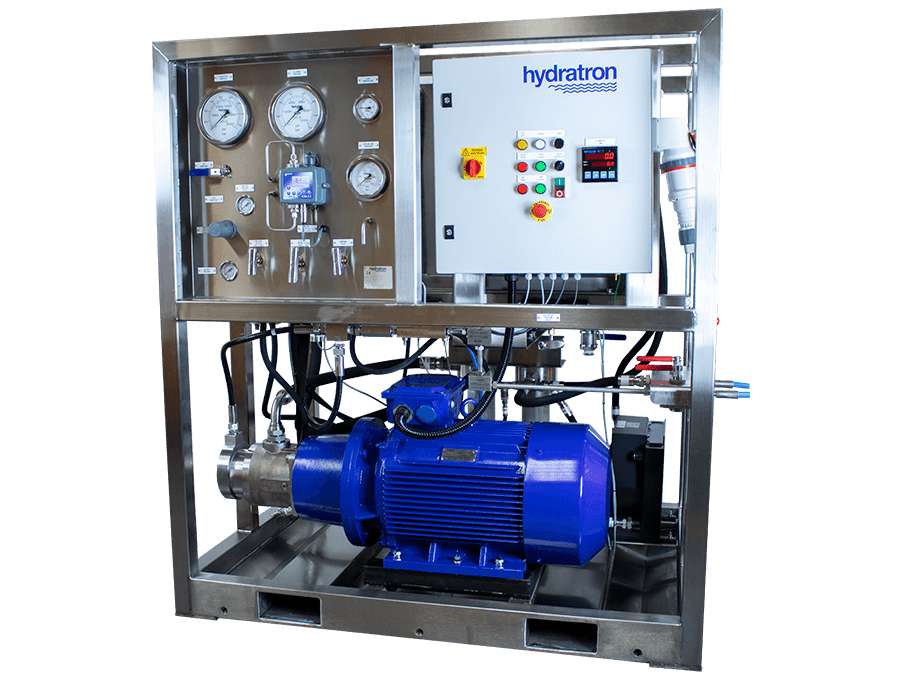

Hydratron Hydraulic Flushing Rigs cover a wide range of applications. Our Flushing Panels are highly engineered to cover both onshore, offshore & marine applications.

Hydraulic Flushing Systems

These filtering systems can be configured in many ways to meet the requirements of customer specifications.

Above you will find images of some of the rigs we have supplied in recent years. Please contact us with details of your Hydraulic Flushing Rig Panel requirements and we will be happy to engineer a proposal to suit your requirements. The Hydraulic Flushing Rigs are crucial care and maintenance system.

Avoid costly repair and replacement bills by using our revolutionary flushing rig range to flush, filtrate and clean contaminants that can build up in your hydraulic systems. Our Flushing Rigs are highly engineered to cover both onshore, offshore & marine applications.

Capable of Pressure Testing

As a subsequent option, an air operated hydrostatic test pump can be included, which adds the dual function of hydrostatic pressure testing to the rig.

Converging to the same outlet as the flushing line, hydrostatic tests can be carried out before or after flushing without the need for breaking or making any connections.

Key Features

- Capable of flushing small components through to large Flow lines & Umbilicals.

- Pressures up to 10,000psi (690Bar).

- Manual or PLC controlled.

- Cleanliness specifications to NAS 1638 class 6 or better.

- Custom designed units to client specifications.

- Robust design with all wetted parts in stainless steel.

- Offshore (DNV lifting frame) available.

- ATEX compliance is available.

- Pressure test capability available.

- In line cleanliness/particle monitoring.

- 3 stage, double function extend/retract open/close feature.

- Option for hydrostatic test pump.

- Custom designed to meet customer’s needs.

Suitable Industries

- Marine

- Oil and Gas

- Aerospace

- Chemical

- Energy

- Food and Drink

Robust design with wetted parts in stainless steel

Turbulent flow for comprehensive flushing

Manual or PLC controlled

ATEX Compliance Available

System Features

3 Micron Filtration

Suction and return filters provide filtration down to 3 microns, offering very high industry standard cleanliness levels for your system. Furthermore, such filtration increases the longevity of the rig’s component parts themselves.

Testing Sample Outlet

With a built-in testing outlet, you can easily sample and analyse your hydraulic system’s fluid for analysis in separate equipment.

Digital Flow Totaliser

Using the rig’s onboard flow control valve together with the digital totaliser display, the desired flowrate through the system can be adjusted to the required level.

Particulate Counter (Optional)

The Inline Contamination Monitor provides real-time measures on the levels of contaminants present in hydraulic systems. The small device reports on saturation levels and has options for moisture and temperature if required. Also, it notifies respecting main international standards.

Air Blast Cooler

To maintain an efficient flushing fluid temperature, all rigs come with an onboard air blast cooler.

Turbulent Flow Pump

Our flushing rigs come with an onboard, electrically driven flushing pump, specified to allow for turbulent flow through your application; offering the best way to dislodge and flush out any contaminants in your system.