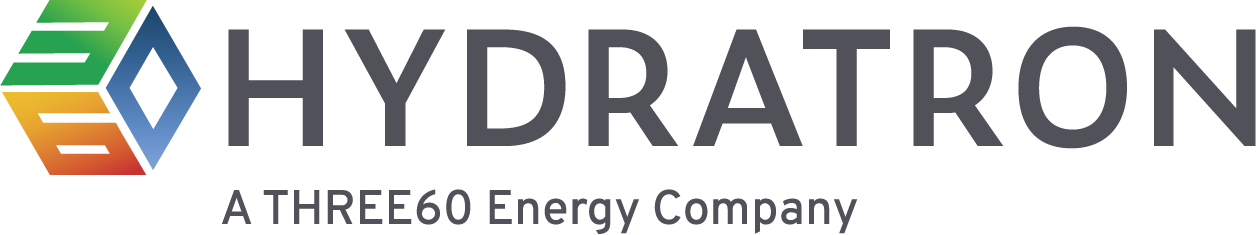

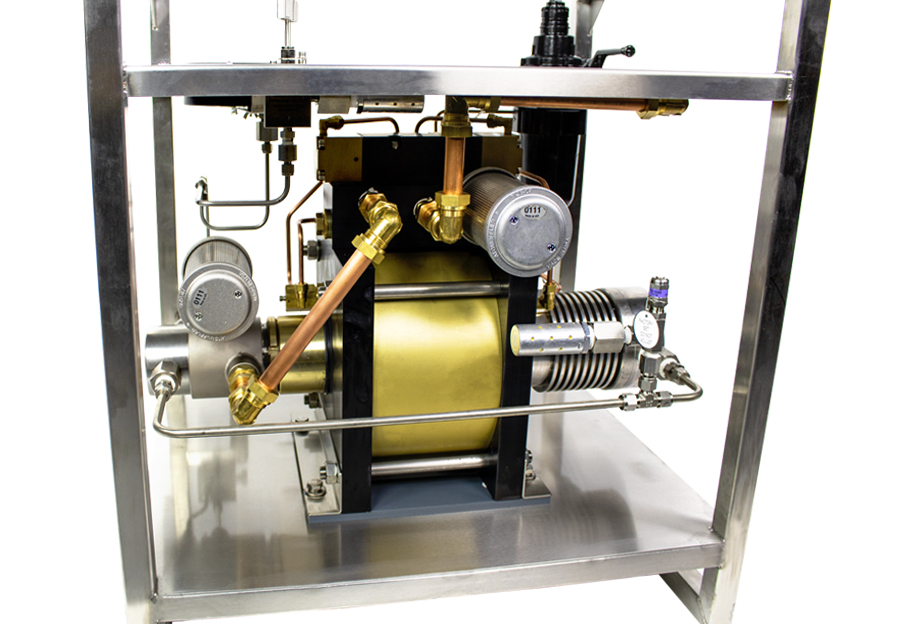

A reciprocating, positive displacement gas pump with a directly coupled, integral linear reciprocating air motor. As a Standard Gas Power Unit (GPU), it responds to customers’ needs for pre-engineered and user-friendly Gas Booster systems.

2-Stage Double Acting Gas Booster Power Unit

Hydratron 2-Stage Double Acting Air Driven Gas Booster is a reciprocating, positive displacement gas pump with a directly coupled, integral linear reciprocating air motor, designed to generate High-Pressure Gas output.

With double-acting models, the pressure increase is made possible by means of the area ratio between the larger diameter air drive piston directly connected to two smaller diameter gas pistons having differing diameters to each other. The reciprocating action of the gas booster draws gas at low pressure into the booster then displaces the gas at a higher pressure output from the booster into a closed system.

On 2-Stage Double Acting models, the inlet gas pressure is used to provide additional energy allowing lower inlet pressures, higher output pressures and higher flowrates to be achieved. When using a 2-Stage Double Acting Gas Booster, care must be taken to ensure that the outlet pressure remains lower than the maximum supply pressure multiplied by the combined area ratio of the 2 Gas pistons since this can cause “interstage stall”. To avoid this the inlet gas pressure can simply be reduced.

The Two-Stage Double Acting Gas Booster Power Unit can be provided as a pump only system.

Key Features

- Ability to stall at a predetermined pressure and hold this fixed pressure without consuming power or generating heat.

- No risk of flame or spark.

- Infinitely variable speed/output flowrate control.

- Infinitely variable output pressure control.

- Easy to apply automatic controls.

- Standard models are suitable for Air, Nitrogen & Helium. Design options are available for more hazardous gases.

- No limit or adverse effects in continuous stop/start applications.

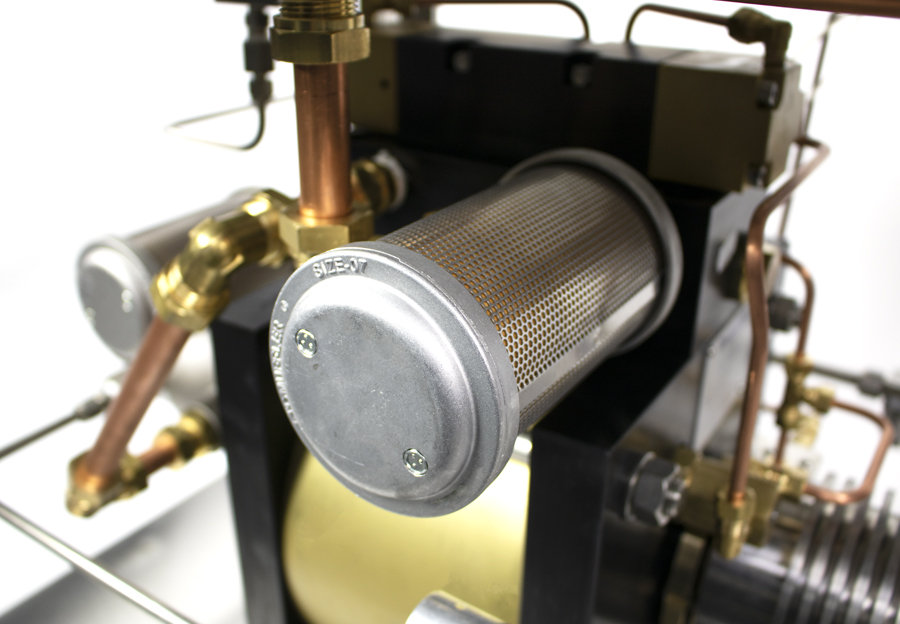

- Proven reliability, easy to maintain and robust.

Specifications

- Air filter, lubricator, pressure regulator, pressure gauge & speed control valve

- 6” (150mm) diameter panel mounted outlet pressure gauge

- Pressure release valve

- All interconnecting pipework & fittings

- Robust Stainless Steel Frame as standard

Options:

- Offshore specification available

- Stroke Counter

- Outlet Pressure Isolation

- On board chart recorder

- Wheels / castors

5,700 to 21,000 PSI

Simple to set automatic controls

Air, Nitrogen, Helium & Other Gases Applications

Easily Maintained

Models For All Pressures

Models & Performance

Model Max Output Pressure @ 100 psi (7bar) Air Drive Displacement/Cycle Max Compression Ratio Supply Pressure to Achieve

Max Output PressureActual Output Pressure (Stall Condition) Data Sheet Psi Bar Cu Ins cc’s Psi Bar GBD7/33 5,700 393 35.8 586.9 60:1 510 35 33PA+4.7PS Download GBD15/66 9,000 621 17.6 288.4 60:1 545 38 66PA+4.4PS Download GBD33/118 14,200 979 7.8 127.9 50:1 685 47 118PA+3.5PS Download GBD66D/186 21,000 1,448 4.0 65.6 40:1 857 59 186PA+2.8PS Download