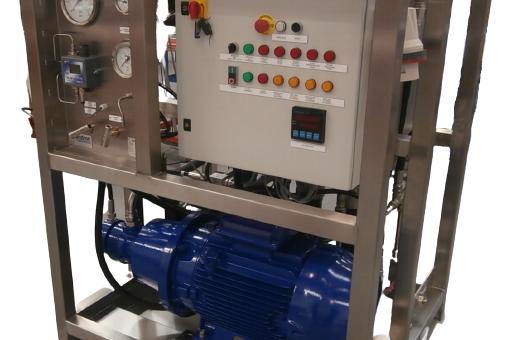

In this feature we are highlighting a project that required our engineers to work closely with the customer to design a flushing HPU that delivered on size, performance and quality.

Requirement

A North African client approached Hydratron to design and manufacture a portable hydrotest / flushing hydraulic power unit (HPU). The HPU would need to achieve NAS class 6 fluid cleanliness and 15,000 PSI test pressure using TOTAL AZOLLA ZS 32 as the operating fluid.

Initial Action

Hydratron system engineers took the clients overview specification of requirement, generated a detailed design and presented this solution to the customer. Following a prolonged commercial and technical bid process, they won the tender to supply the equipment to an end user based in Algeria.

Challenges

On completion of the design, Hydratron provided the general assembly drawings to the customer for approval and it was at this juncture that we were informed of significant additional requirements and alterations to both the design and functionality of the rig.

We were informed that the end user needed the rig to fit the specific footprint of a pickup vehicle trailer for ease of transportation between sites. This change meant that Hydratron’s team of specialist engineers had to go ‘back to the drawing board’ to redesign the product to fit the end users requirements, all without compromising on the performance or quality and ensuring that the equipment was still fit for their application.

Solution

After several meetings with the end user via video conference, Hydratron’s design engineers were able to make a number of suggestions to mitigate the space issue and reduce the overall size of the HPU, all whilst keeping the main functionality of flushing and imperative components intact.

The following changes were made:

- Removal of the hydrostatic test line and pump; this was supplied as a standalone item.

- Reduced the tank capacity from 300 to 150 litres.

- Removal of the castors and re-design of the layout of some key components.

With these changes the general assembly drawing was submitted with the HPU measuring 1250mm wide, 1200mm front to back and 1510mm high. The new, portable and compact design was subsequently approved and supplied to the customer.