In this feature we are highlighting an innovative valve testing solution which was delivered and installed in our Global customers facility in the Caspian Region.

The client’s pressure testing requirements were complex and therefore called on the expertise of the entire Hydratron team, testing with both gas and water up to pressures of 690 Bar, accommodating valve sizes ranging from 1/2″ up to 24″ with various orientations from single flange type relief valves to angle pattern or straight pattern control valves.

Customer Requirement

An international customer approached Hydratron to find a solution for their valve testing requirements for a new testing facility based in the Caspian Region. The client’s pressure testing requirements were complex and therefore called on the expertise of the entire Hydratron team, testing with both gas and water up to pressures of 690 Bar, accommodating valve sizes ranging from 1/2″ up to 24″ with various orientations from single flange type relief valves to angle pattern or straight pattern control valves.

This variety required a special approach to the work holding logic of the system.

The Client also had a strict requirement for onsite training to certify their operators in the use of this new test system, ensure that Hydratron service engineers would be available to carry out service work on site as required for normally safe operation and that spares would be readily available should they be required.

Our Approach

Hydratron’s design engineers took the time to understand the customers requirements by engaging with their engineering and operations teams. They gained a deep understanding of the required functionality, testing procedures and any space and layout constraints on site; this information allowed the Hydratron team to begin designing the proposed solution.

Functionally, the unit needed to complete valve body testing, upstream and downstream seat tightness/leakage testing and the test data also needed to be logged and retained for certification. Workshop space was discussed to ensure the layout and orientation of the complete system fitted with the clients’ spatial constraints. 24″ clamping systems are physically large units, so it was important to gain an understanding of the workspace available.

Hydraton engineers also assessed testing and valve setup times so that they could demonstrate the estimated time savings the new system would offer the customer as part of their proposal.

Challenges

One of the biggest challenges to overcome was to design a concept for the clamping system which would cater for the large variance in type and size of valves. In relation to testing times, along with the prefill time, a main area to be considered was comparing existing setup and test times which involved manually flanging and torquing the valves, to a hydraulic clamping system.

Solution

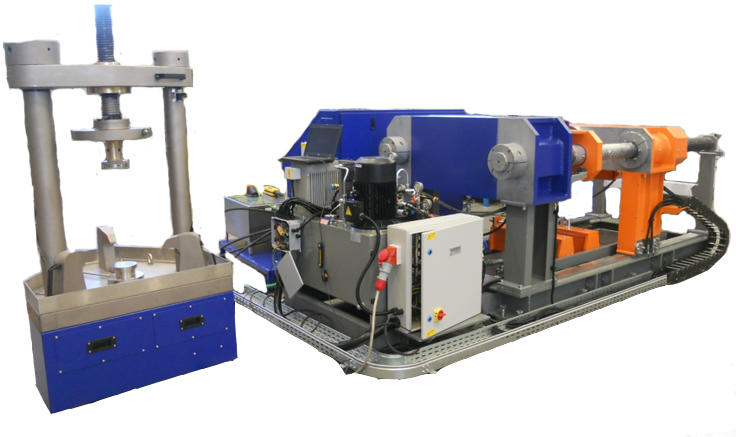

The optimal solution was to provide two separate clamp units:

- 1 x 100 tonne system suitable for 1/2″ to 12″ valves, incorporating a universal clamp arrangement to allow for relief valve and control valve testing.

- 1 x 250 tonne system suitable for larger valves, this introduced the flexibility required to cater for the large range of valve to be covered.

Internal volumes were considered to get an estimate for prefilling times, this allowed for the accurate selection of a suitably sized centrifugal vertical multistage pump, to prefill the valves. Setup times for manually flanging and torquing the valves were supplied by our client and compared to a hydraulic clamping system, this demonstrated a significant saving in time for test setup.

Coupled with the saving in man hours, the hydraulic clamping system introduced a whole host of safety benefits. Both the clamping units were to be operated from one single central control console, remotely located to ensure the operators were safely away from the high pressure areas when carrying out testing. Functionality and Safety management was carried out by our PLC and touchscreen HMI system.

Training and after sales service

Hydratron attended site in the Caspian region following delivery of the equipment, we fully commissioned the system and completed operator training, after which they received certificates of competence in its use.